About us

About us

Potent Mechanical & Industrial (Xiamen) Co., Ltd. is established in June 2001, with its headquarter located at Xiamen Guanyinshan International Business Center in Xiamen, and its factory at Tong’an Industrial Concentration Zone in Xiamen.

-

Company Profile

-

History

-

Honor

-

Organizational

-

Partners

Industry field

Industry field

A comprehensive service provider integrating power project investment, EPC general contracting, operation and maintenance.

-

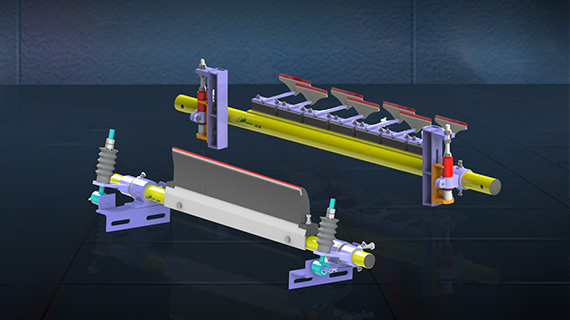

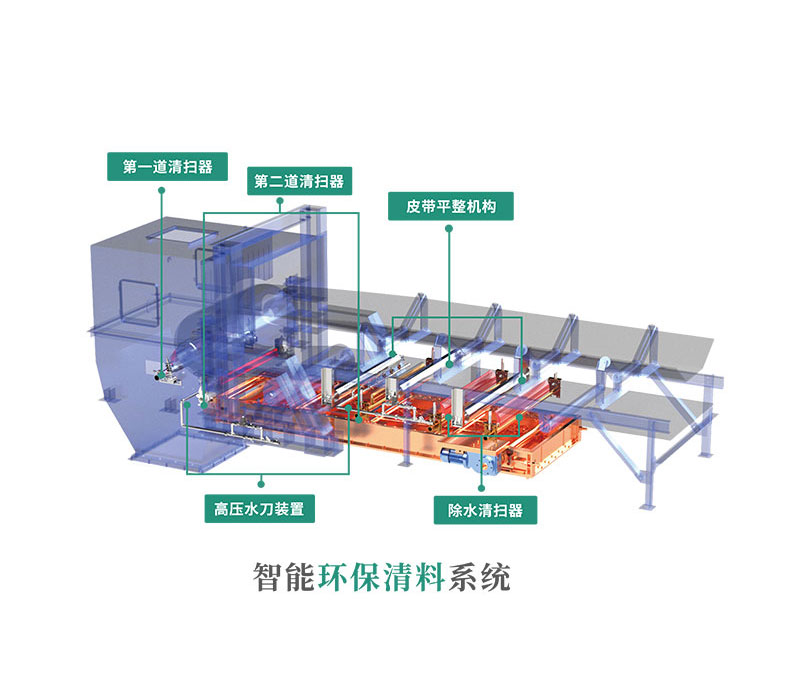

Bulk materials conveyance and storage

-

Pertochemical modularization

-

Thermal Engineering

-

Material handling energy storage

Products

Products

Independent research and development, innovative products, promote product independence and controllability to better serve customers.

-

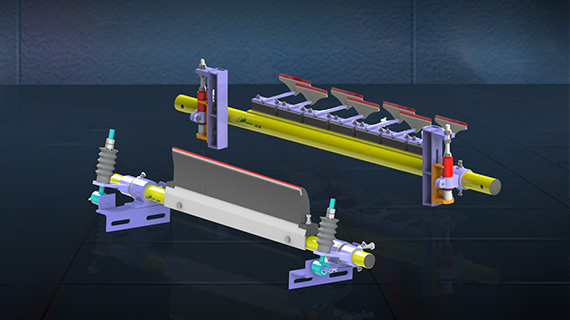

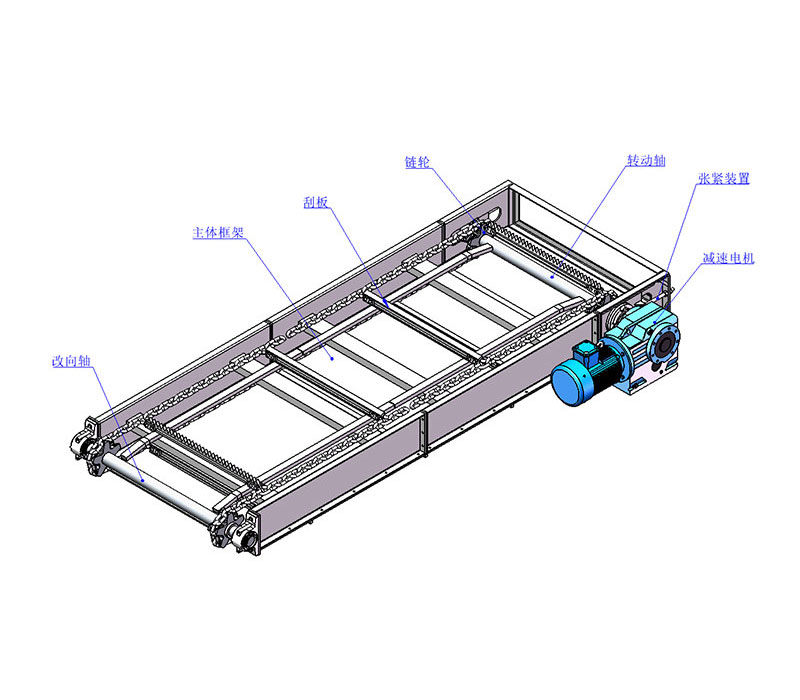

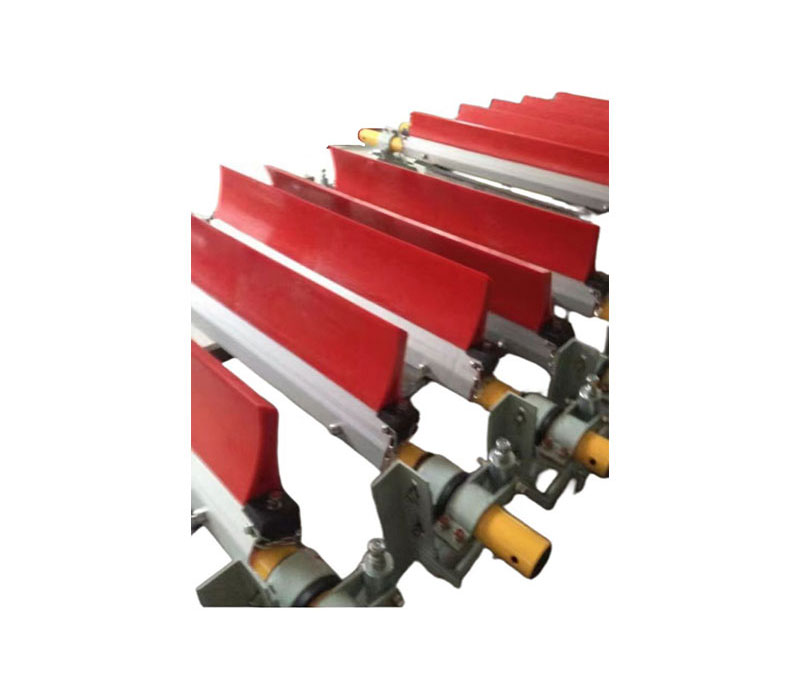

Belt cleaner

-

DEM designed curved chute

-

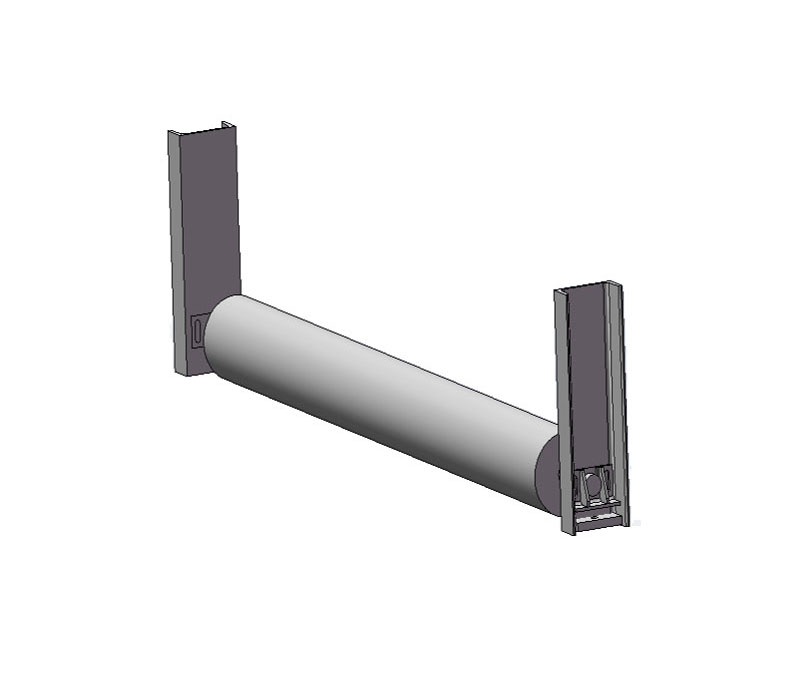

Impact bed

-

Grooves of skirt-board

-

More Products

News

News

Get to know the latest developments of Potent Mechanical.

-

News Center

Contact us

Contact us

We provide you with professional pre-sales consulting services and excellent after-sales service.

-

Contact Us

-

Message

+86-592-5853191

+86-592-5853191 +86-592-5810190

+86-592-5810190

Company address:F13, No. 168, East Tapu Road, Siming District, Xiamen, China

Company address:F13, No. 168, East Tapu Road, Siming District, Xiamen, China Factory address : No. 6, Tongfu Road, Tong’an Industrial Concentration district, Tong’an District, Xiamen, China

Factory address : No. 6, Tongfu Road, Tong’an Industrial Concentration district, Tong’an District, Xiamen, China